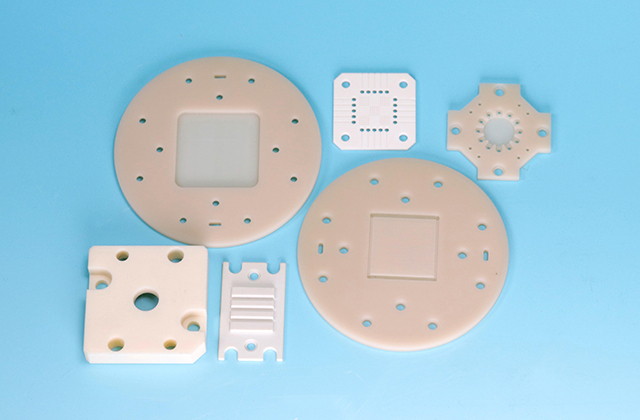

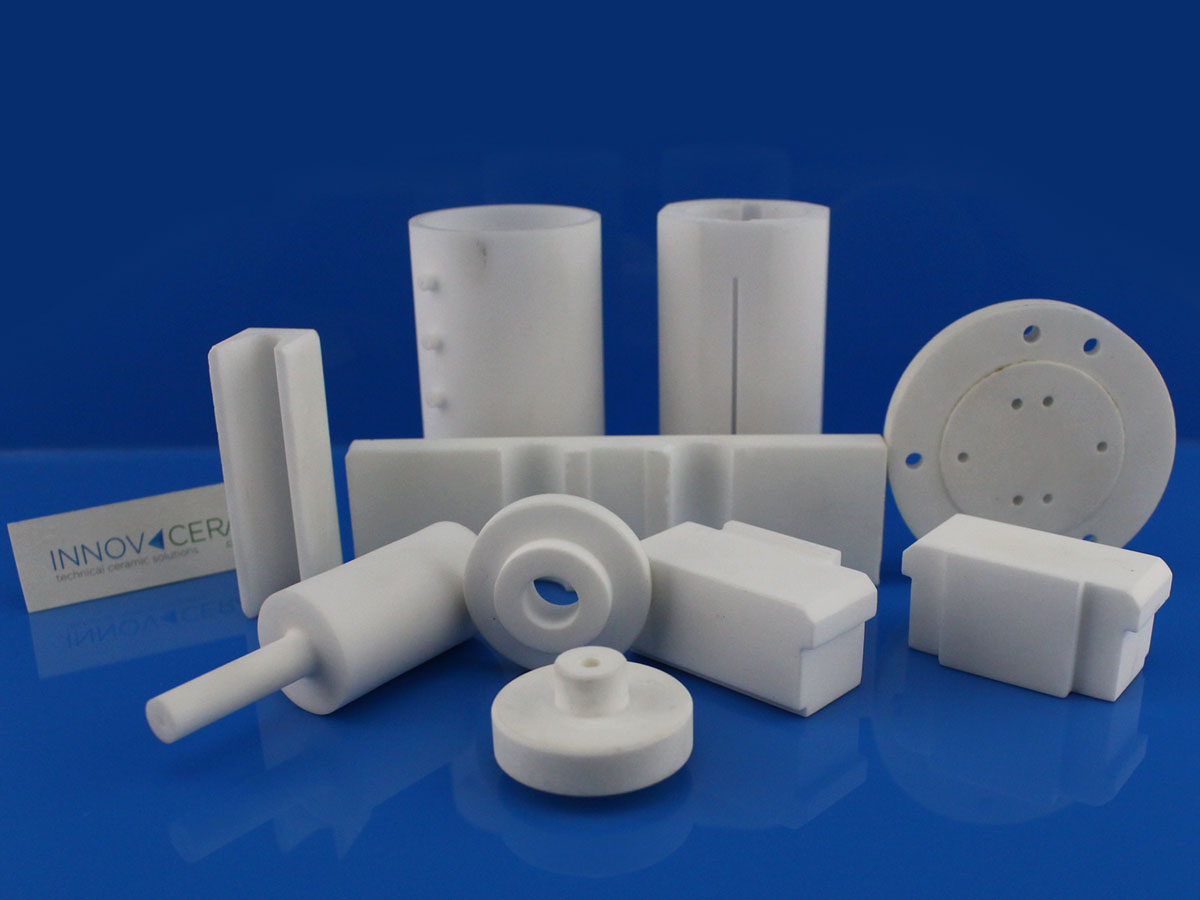

No machining all depending upon the requirements of the oem ceramic part the geometry and final tolerances can oftentimes be achieved during the near net shaping process.

How to machine machinable ceramics.

Macor machining guide how to machine macor.

Choose from our selection of machinable ceramic including easy to machine glass mica ceramic ultra high temperature ceramic and more.

Also fine diamond machining is used at ceramco to machine non ceramics including quartz.

Macor is a corning inc.

For the low to medium volume precision work macor is a material that even a modestly equipped shop can machine into precision ceramic parts.

Corning is well know for its glass products and macor is a hybrid machinable glass ceramic that can be fabricated into intricate shapes with tolerances on the order of 0 0002 in with ordinary carbide tooling.

As with most other hard machining operations coolant must be used to dissipate heat and to flush away the ceramic swarf which can damage both the machine and the production.

That is they can be turned milled drilled and saw cut without the need for diamond tooling.

Machinable is a term used to describe ceramic materials that after sintering can be machined with traditional metalworking machine tools.

Combat bn machinable ceramics grade a.

Combat machinable ceramics grade a uses b 2 o 3 binder system to add mechanical strength to hot pressed hbn.

Additionally materials like silicon carbide sic may not fit the precise definition of a ceramic material but they can still be classified as part of the ceramic family.

Macor is one of the few ceramics that can be machined using regular metal working tools.

Ceramics can be made from several different types of hard metal oxides or nitrides.

This is the most cost effective solution.

Moreover the loose diamond debris can scratch or mar the ceramic part.