For example in a room that s running over 40 feet in length we recommend a transition molding to divide the floor and introduce an expansion gap hidden by the t molding within a reasonable distance.

How to keep floor transition t molding down.

How to install laminated flooring transition molding.

Installing flush transitions with a floating floor flush transition moldings are commonly used to complement nailed down or glued down wood floors.

Ifloor shows you how to install a t molding between your floors or in doorways between two types of flooring.

Although the most common transition for t molding is doorways another function of t molding is joining hardwood floors in large areas.

Often referred to as a floating floor because it does not attach to.

Long runs of hardwood floors need to allow for expansion and contraction.

In some cases weight may have to be applied to the molding to keep it in contact with the adhesive until it cures.

Laminate flooring is one of the least expensive floor coverings available.

Removing t molding is similar to removing other trim just make sure to work with the shape of the t molding to avoid breaking it.

Stair nosing is the most common transition molding used in installations.

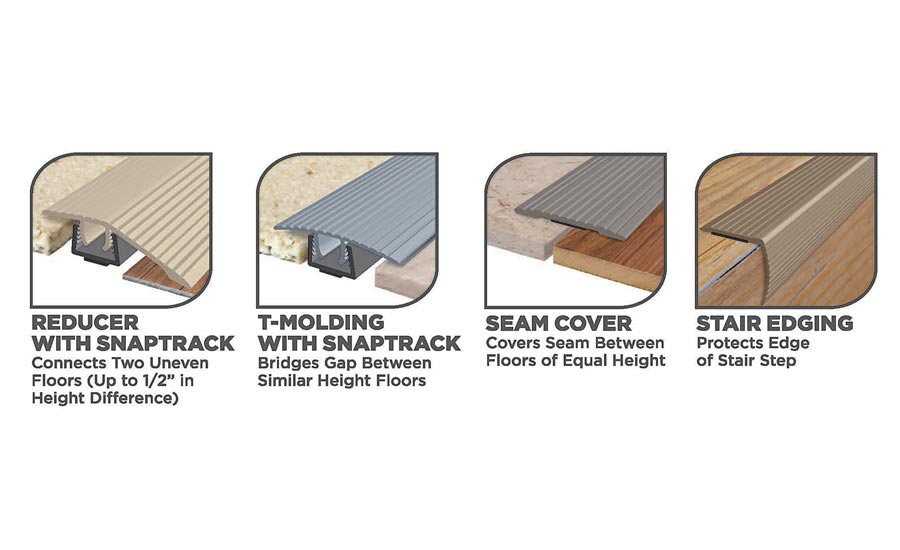

T molding is used to join flooring transition from one flooring material to another or as edging along the end of flooring.

This fine molding takes your flooring down a ledge with style by providing a rounded drop.

Most t molding available is made of plastic composite or other synthetic materials although natural wood t molding is available.

T moldings are used to create a transition between two floors of equal thickness.

Stair nosing is available in flush and overlap and should be chosen depending on installation method.

Commonly used transition moldings.

Floating floors require over lap transition moldings to be used.

If you are installing a new floor the t molding needs to be removed and replaced.

Typically homeowners have the option of.

The easiest transition piece to recognize is the t molding because of its distinctive t profile shape.

Any floor longer than 40 feet 12 2 meters should have an expansion gap and this is where a t molding would do the job.