Structure and defects in powders and powder compacts are examined in detail to determine their formation mechanisms and their relevance to the production of high quality ceramics.

How to introduce defects in ceramic powders while pressing.

Before pressing the powder is fully prepared as explained in the powder metallurgy section.

The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage.

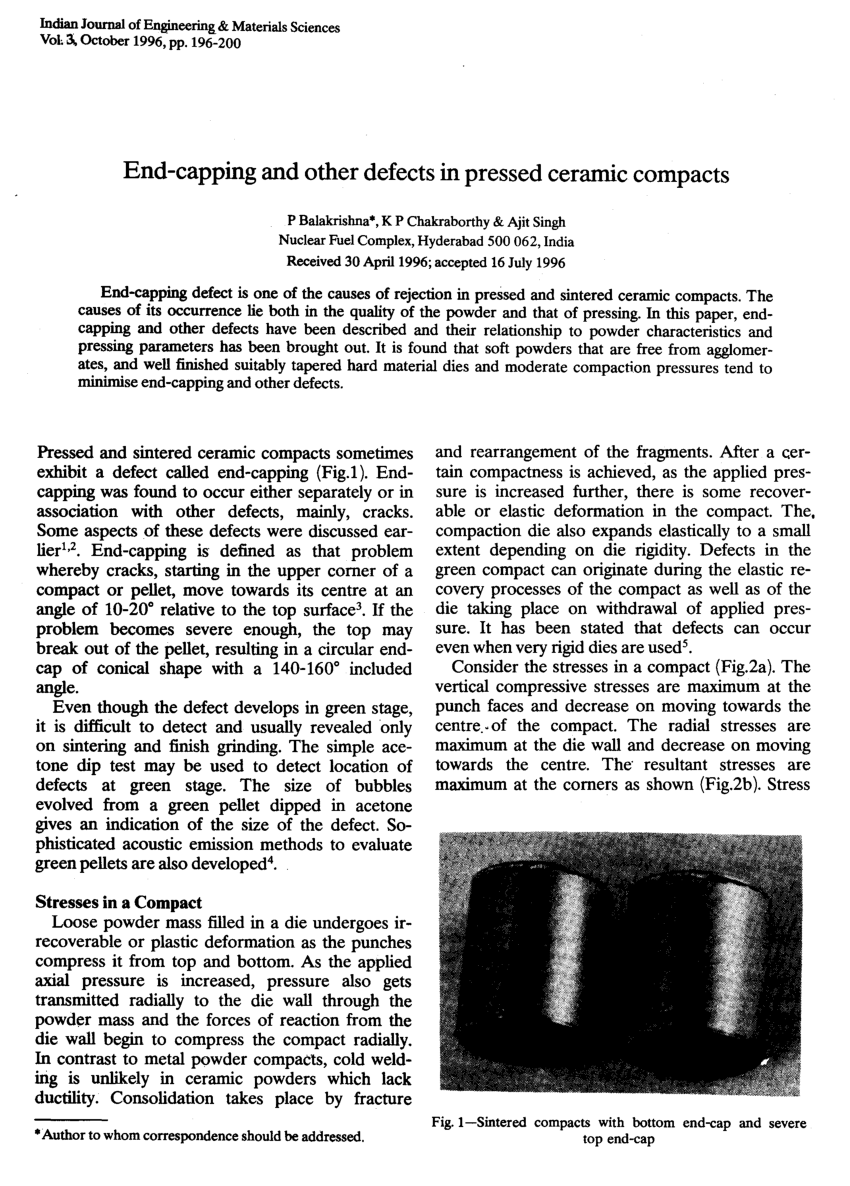

In this paper end capping and other defects have been described and their relationship to powder characteristics and pressing parameters has been brought out.

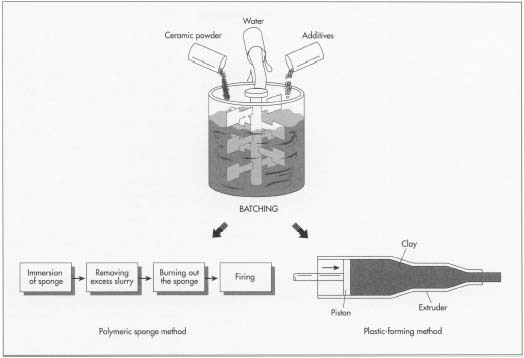

A general processing flow diagram for forming a ceramic product using uniaxial dry pressing is shown in figure 1.

In addition to the powder constituents binders deflocculates and lubricants may also be present in the mixture.

The causes of its occurrence lie both in the quality of the powder and that of pressing.

General processing flow diagram for fanning by powderpressing.

Gourvès balkema rotterdam pp.

New characterization tools that are indispensable in the characterization of defect structure are described with the aid of schematic illustrations.

End capping defect is one of the causes of rejection in pressed and sintered ceramic compacts.

End capping defect is one of the causes of rejection in pressed and sintered ceramic compacts.

Compaction of ceramic powders is a forming technique for ceramics in which granular ceramic materials are made cohesive through mechanical densification either by hot or cold pressing.

Bruch 1967 and many other powders produced by precipitation plasma spraying and cryogenic techniques.

The causes of its occurrence lie both in the quality of the powder and that of pressing.

1989 fabric tensor showing anisotropy of granular soils and its application to soil plasticity in powders and grains proceedings of the 1st international conference on micromechanics of granular media clermont ferrand france 4 9 september 1989 eds j.

The batch is comprised of powders and granular materials that on firing consolidate and shrink into a more dense mass.

Jill glass and kevin g.

However it is often necessary to dry press ceramic parts from powders with a finer mean particle size such as some ferrite powders motyl 1963 highly reactive alumina powders berrin et al 1972.

Press powder t eject pressed compact t figure 1.

Ceramic powder compaction s.

Ewsuk introduction powder pressing either uniaxially or isostatically is the most common method used for high volume production of ce ramic components 1 5 the object of a pressing process is to form a net shaped homogeneously dense powder compact that is nominally free of defects.

The resulting green part must later be sintered in a kiln.